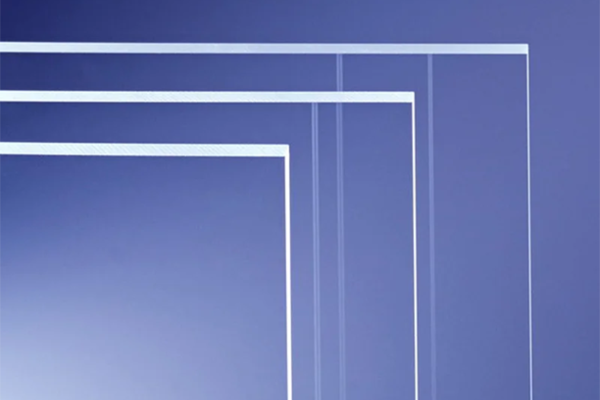

Domestic Alkali-Free Glass

Domestic alkali-free glass is a specialized type of glass characterized by its low alkali oxide content, typically less than 0.1%. This composition provides several advantages, particularly in high-tech applications.

- Details

★High Chemical Stability: Alkali-free glass exhibits excellent resistance to chemical corrosion, making it suitable for use in harsh environments and applications where chemical durability is essential

★Low Thermal Expansion: This type of glass has a low coefficient of thermal expansion, which allows it to maintain dimensional stability under varying temperature conditions, reducing the risk of cracking or deformation.

★Enhanced Mechanical Strength: Alkali-free glass is known for its superior mechanical strength, which makes it ideal for applications requiring durability and resistance to impact.

★Excellent Optical Clarity: The glass provides high transparency and clarity, making it suitable for optical applications such as display screens and lenses.

★Environmentally Friendly: Being free from hazardous alkali metals, alkali-free glass aligns with modern environmental standards, making it a safer choice for both manufacturers and consumers.

Key Features

★Low Alkali Content: The minimal presence of alkali oxides ensures that the glass does not degrade the properties of thin films, making it suitable for sensitive electronic applications.

★High Thermal Dimensional Stability: Alkali-free glass exhibits a high strain point and a low thermal expansion coefficient, allowing it to maintain dimensional stability during high-temperature processes, such as those used in the production of liquid crystal displays (LCDs) and organic light-emitting diodes (OLEDs).

★Chemical Stability: The glass is chemically inert, making it resistant to various treating agents used in semiconductor processes. This property helps maintain the quality of the surface during manufacturing.

★Smooth Surface Finish: Glass substrates produced from alkali-free materials have flat precision surfaces, which are essential for high-quality optical and electronic applications.

★Environmentally Friendly: This type of glass is free from hazardous substances like arsenic (As) and antimony (Sb), aligning with modern environmental standards.

Applications

★Display Technology: Used as substrates for LCD and OLED displays, where dimensional stability and surface quality are critical.

★Thin Film Formation: Suitable for various thin film applications in electronics due to its chemical stability and low alkali content.

★Semiconductor Manufacturing: Employed in processes that require high precision and resistance to chemical treatments.

Overall, domestic alkali-free glass is an essential material in the electronics industry, providing reliability and performance in advanced display technologies and semiconductor applications.