SCHOTT BOROFLOAT® 33 Glass

SCHOTT BOROFLOAT® 33 is a UV-NIR transparent borosilicate float glass known for its excellent optical properties and smooth, low scatter surfaces. It is a high-performance, cost-effective material ideal for mass production of windows, mirrors, filters, display glass, and 3D build platforms. With outstanding thermal resistance and sharp impact crack resistance, it is perfect for challenging environments.

- Details

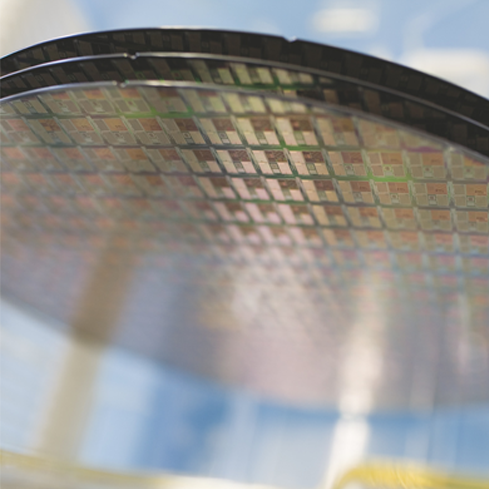

Buy Borofloat 33 Glass Wafer – High-Quality, Customizable Options Available

AtLIGHTING, we are a leading Borofloat 33 glass supplier offering top-grade borosilicate glass wafers with excellent optical and thermal properties. Borofloat 33 is a highly versatile material, perfect for advanced precision optics, thermal management, and other high-demand applications.

Why Choose Borofloat 33 Glass?

Borofloat 33 glass is well-known for its low thermal expansion coefficient, providing stability in environments where temperature fluctuations are common. With high thermal shock resistance of up to 300°C and exceptional optical transmittance of 91% at a wavelength of 600 nm, this material is ideal for precision applications across industries like:

MEMS and semiconductor technology

Optical components and lasers

Astronomy and scientific research

Microfluidics and advanced micro-manufacturing

Custom Glass Solutions Tailored to Your Needs

We offer Borofloat 33 glass wafers in standard sizes of 2″, 3″, 4″, 100mm, 150mm, and 200mm, with the option for custom specifications to meet your exact project requirements. Whether you need unique diameters, customized cuts, or special treatments, our team, as a custom glass manufacturer, is ready to deliver tailored solutions to meet your specific needs.

Precision Processing for Flawless Results

All of our Borofloat 33 glass wafers are produced under rigorous quality control processes to guarantee high consistency and reliability. Our advanced processing capabilities include:

Precision CNC machining for custom shapes and dimensions

Grinding and polishing for smooth surfaces

Metrology for precise dimension measurement

Cleanroom handling and packaging to ensure contamination-free products

At LIGHTING, we combine our expertise in custom glass manufacturing with cutting-edge technologies to provide high-quality, reliable Borofloat 33 glass wafers for all your demanding applications.

Fast Fulfillment, High-Quality Borofloat 33 Glass

We ensure rapid delivery with fast fulfillment options, all backed by our customer-focused approach to meeting your precise requirements. Whether you’re purchasing small quantities for prototyping or large volumes for production, trust us as your Borofloat 33 glass supplier for the highest standards in material quality and service.

BOROFLOAT® 33 Basic properties:

Good light transmittance, low fluorescence intensity and high ultraviolet and infrared transmittance.

Low coefficient of thermal expansion, strong thermal shock resistance and long-term operating temperature up to 450℃.

Good chemical stability, high resistance to corrosion of water, strong acid, strong alkali and organic material.

Scratch resistance, high hardness and 20% lower density than ordinary sodium-calcium glass

Low alkali content, can be used as an excellent electrical insulator.

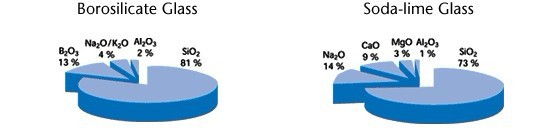

| Technical parameters: | Chemical composition: | |

| Density (25℃) | 2.2g/cm2 |  |

| coefficient of expansion (ISO 7991) | 3.25′10-6k-1 | |

| Light transmittance | 91% | |

| Softening point | 820℃ | |

| Short-temm use <l0h | 550℃ | |

| Long-term use of l0h | 450℃ | |

| Refractive index (587.6nm) | 1.47140 | |

| Knoop hardness | 480 | |

BOROFLOAT® 33 Specifications and Thickness:

Thickness: 0.70 ~ 25.40mm Standard size: 1150 ‘850mm

Thickness: 3.30 ~ 15.00mm Standard size: 2300 ‘1700mm

Thickness: 16.00 ~ 25.40mm Standard size: 1700 ‘1300mm

Laser gauges are used to measure sheet thickness during production. Other available on request

Thermal properties of BOROFLOAT® 33:

Calibrated dimensions, thicknesses and tolerances.

The low coefficient of thermal expansion, strong resistance to thermal shock, and ability to withstand temperatures up to 450°C for long periods of time make BOROFLOAT® 33 particularly suitable for applications that require good temperature stability (e.g., the inner panels of pyrolytic self-cleaning ovens, the outer panels of high-power stage lights and high-power floodlights).

| Linear expansion | α (20 – 300 °C) | 3.25 x 10-6 K-1(ISO 7991) | Note: |

| Heat Capacity | Cp (20 – 100°C) | 0.83 KJ x (kg x K)-1 | This operating temperature is applicable only if the following values of in-plate temperature difference (RTG) and thermal shock resistance (RTS) are met simultaneously. |

| Thermal conductivity | λ (90°C) | 1.2 W x (m x K)-1 | |

| Operating temperature (long-term) | δ max (< 10 h) | 550°C | |

| Operating temperature (short-term) | δmax (≥ 10 h) | 450°C |

The same-sheet temperature difference (the performance of a piece of glass to with stand the temperature difference between the heating center and the cooler edge)

Test method: the area of about 25 × 25cm 2 glass plate is heated to a certain temperature, while its edges are kept at room temperature. The glass breakage rate due to thermal stress should be no more5%. Use before testing SIC 40-type coarse sandpaper polishes the glass plate to simulate extreme surface wear that may occur in use.

| RTG | |

| 1 – 100hours | 90 K |

| > 100hours | 80 K |

Thermal shock resistance (the performance of glass to withstand temperature quenching)

Test Method: the area of about20 × 20cm 2 glass plate is heated in a furnace and then used.50ml of cold water (room temperature) was poured over the center to cool. The breakage rate of the glass should not be greater5%. Use before testingSIC 220 coarse sandpaper polishes the glass plate to simulate the surface condition after actual use.

| Glass thickness | |

| ≤ 3.8mm | 175 K |

| 5.0 – 5.5mm | 160 K |

| 6.5 – 15.0mm | 150 K |

| > 15.0mm | 125 K |

BOROFLOAT® 33

| Work Point | 104 dPas | 1270°C |

| Softening Point | 10 7.6 dPas | 820°C |

| Annealing Point | 10 13 dPas | 560°C |

| Strain Point | 10 14.5 dPas | 518°C |

| Transition Temperature (Tg) | 525°C |

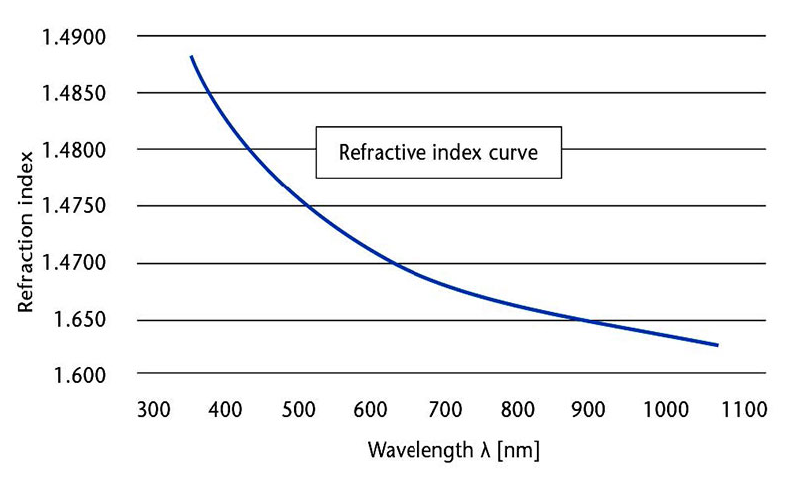

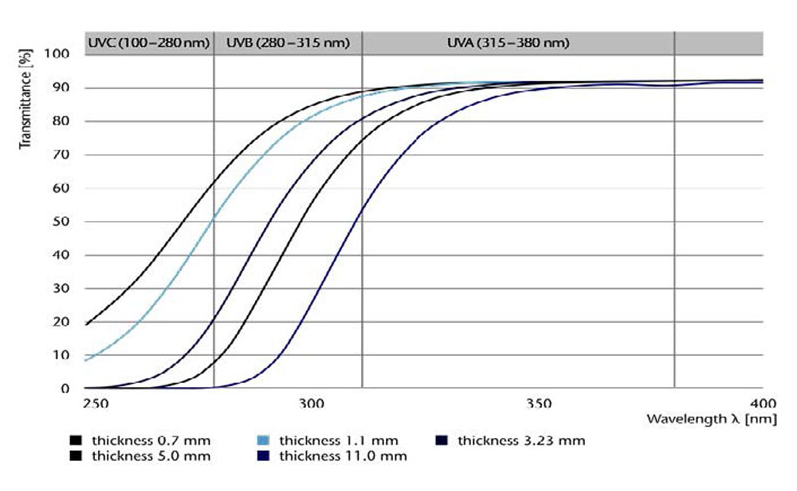

BOROFLOAT® 33 Optical Characteristics:

BOROFLOAT® 33is a clear, colorless glass. Excellent transmission in the ultraviolet and visible near-infrared light range makes BOROFLOAT® 33 has become a kind of application in a variety of floodlights, high-power spot lights and sunbeds (operating temperature up450 ℃) ideal material.BOROFLOAT® 33 glass is very low, good surface quality is flat and uniform, can be widely used in optics, optoelectronics, photonics and analysis equipment and other fields.

| WavelengthΛ(nm) | 435.8 | 479.9 | 546.1 |

| Refractive Indexn | 1.48015 | 1.47676 | 1.47311 |

| WavelengthΛ(nm) | 589.3 | 643.8 | 656.3 |

| Refractive Indexn | 1.47133 | 1.46953 | 1.46916 |

| Abbe Constant | Ve=(ne-1)/(nF’-nC’) | 65.41 | |

| Refractive Index | nd(λ587.6 nm) | 1.47140 | |

| Dispersion | nF-nC | 71.4 × 10-4 | |

| Stress Optical Coefficient | K | 4.0 × 10-6mm2N-1MPa-1 |

BOROFLOAT® 33

Some materials are excited by high-intensity high-frequency shortwave and have the property of releasing electromagnetic radiation. This property is called fluorescence. It is affected by the purity and structural characteristics of the material, but also depends on the single pulse energy, pulse frequency and the excitation wavelength of the radiation.

BOROFLOAT® 33 is a highly transparent glass that exhibits very weak fluorescence in the visible wavelength range.

selected standard lasers and wavelengths:

| Wavelength (nm) | Laser Medium | Wavelength (nm) | Laser medium | Wavelength (nm) | Laser medium |

| 308 | XeCI | 488 | Ar | 1047 | Nd:YLF |

| 325 | HeCd | 514.5 | Ar | 1053 | Nd:YLF |

| 337 | N2 | 532 | Nd:YAG | 1064 | Nd:YAG |

| 350 | XeF | 632.8 | HeNe | 1153 | HeNe |

| 351.1 | Ar | 694.3 | Ruby | 1319 | Nd:YAG |

| 363.8 | Ar | 730-780 | Alexandrite | 1730 | Er:YLF |

| 427 | N2 | 850 | Er:YLF | 2060 | Ho:YLF |

| 441.6 | HeCd | 905 | GaAs | 10640 | CO2 |

BOROFLOAT® 33 Electrical Characteristics:

Due to the low alkali content,BOROFLOAT® 33 can be used as a high insulator, so it is suitable for applications at high temperatures (up450 ℃) under the need for materials with good non-conductive properties.

Because of the unique structure of borosilicate glass,BOROFLOAT® 33 has neutron absorption.

| Dielectric Constant | εr | (25 ℃,1 MHz) | 4.6 | |

| Leakage Constant | tan δ | (25 ℃,1 MHz) | 37 x 10-4 | |

| Resistivity Logarithm | lg ρ | 250 ℃ | 8.0 Ω x cm | |

| 350 ℃ | ||||

BOROFLOATBF33 is available in model Schott borosilicate glass:

| Thickness (mm) | Tolerance (mm) |

| 0.70 to 2.25 mm | ± 0.05 |

| 1.10 | ± 0.05 |

| 2.00 | ± 0.05 |

| 3.80 | ± 0.20 |

| 5.00 | ± 0.20 |

| 6.50 | ± 0.20 |

| 11.00 | ± 0.30 |

| 25.40 | ± 1.00 |

BOROFLOAT® Applications:

BOROFLOAT® chip applications

BOROFLOAT® Biotechnology applications

BOROFLOAT® optical lens applications

Order Borofloat 33 Glass Wafer Today

Browse our selection of Borofloat 33 glass wafers and order online today. Contact us for custom quotes or technical support, and let us help you find the perfect glass solution for your next project.